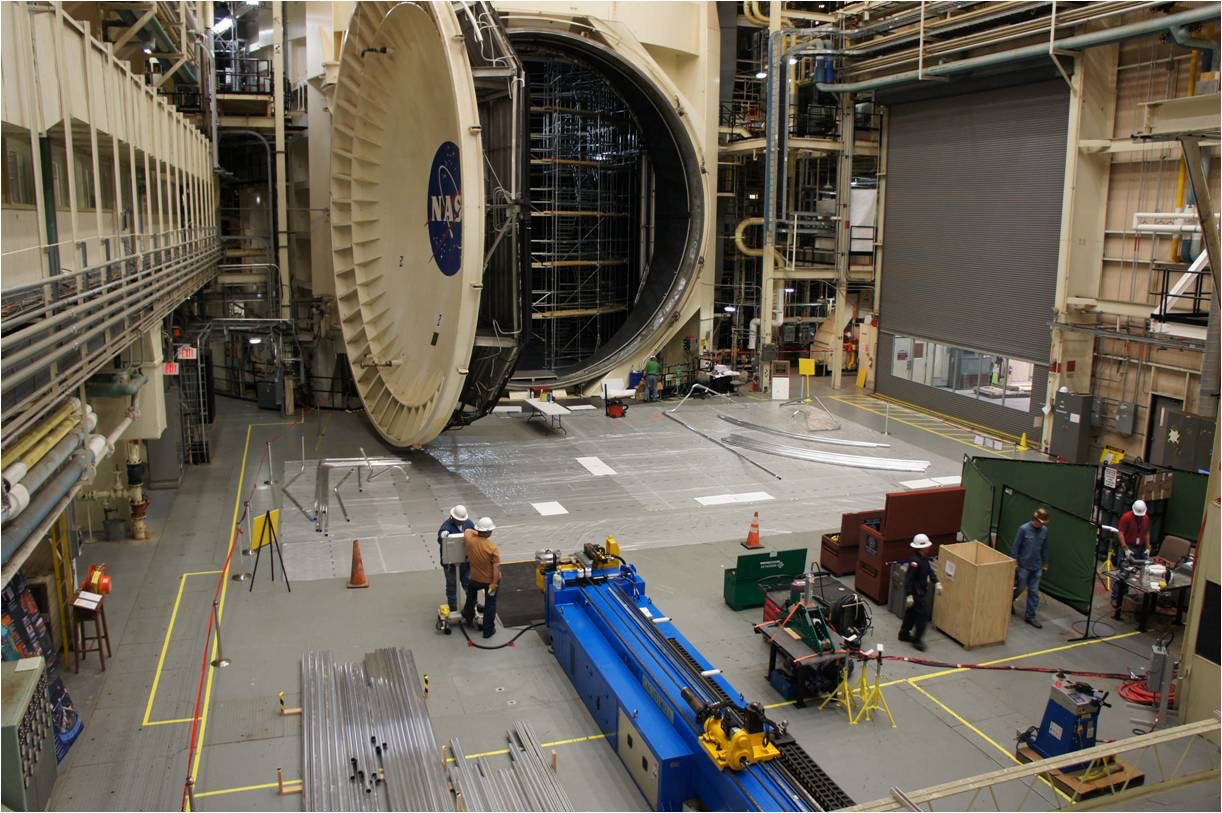

Aerospace

Aerospace Tube Bending Applications

The aerospace industry has a very wide variety of tube bending applications. Expensive thin-wall alloys such as Titanium, Inconel, Monel, Aluminum, and a variety of stainless steel grades, are often utilized where high strength, but light weight is a requirement. Manufacturing tolerances are usually very tight and the ability to communicate with a tube inspection system is often a prerequisite. Aerospace applications tend to be lower in volume, but the requirement for accuracy and repeatability makes them excellent candidates for all-electric CNC tube benders.

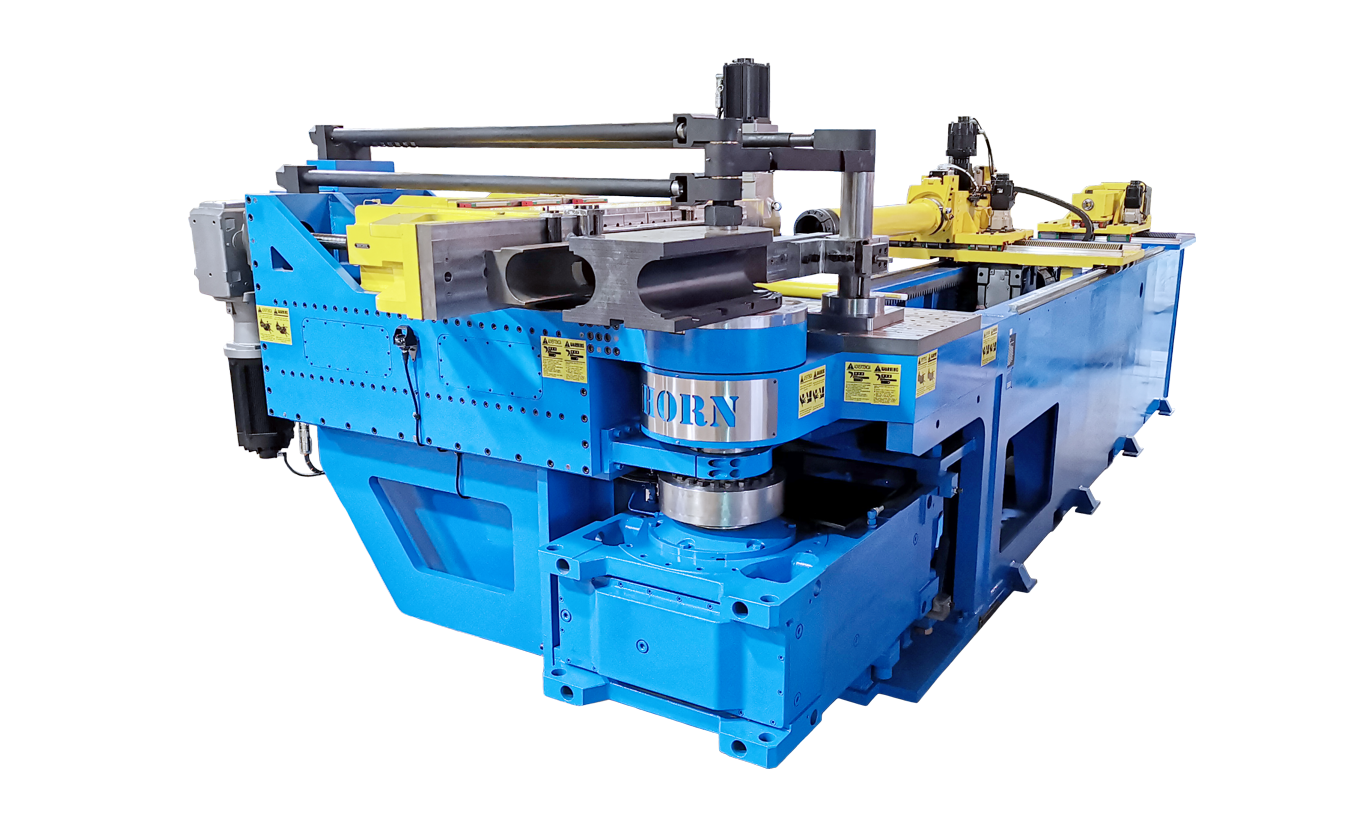

All Electric CNC Tube Benders For Aerospace Tube Bending

- All axes are electric servo driven. This allows for automatic setup on the machine as there are no manual adjustments.

- All-Electric benders provide the most accurate bending and positioning in the industry, and are ideal for tight tolerance bending.

- BendPro G2 V3 provides many options for increased productivity. These include offline development software, CAD import, CMM interface, and IoT capabilities.

- All-Electric benders are “Green Machines”. They use power only when required, and they are very quiet because there are no hydraulic systems.