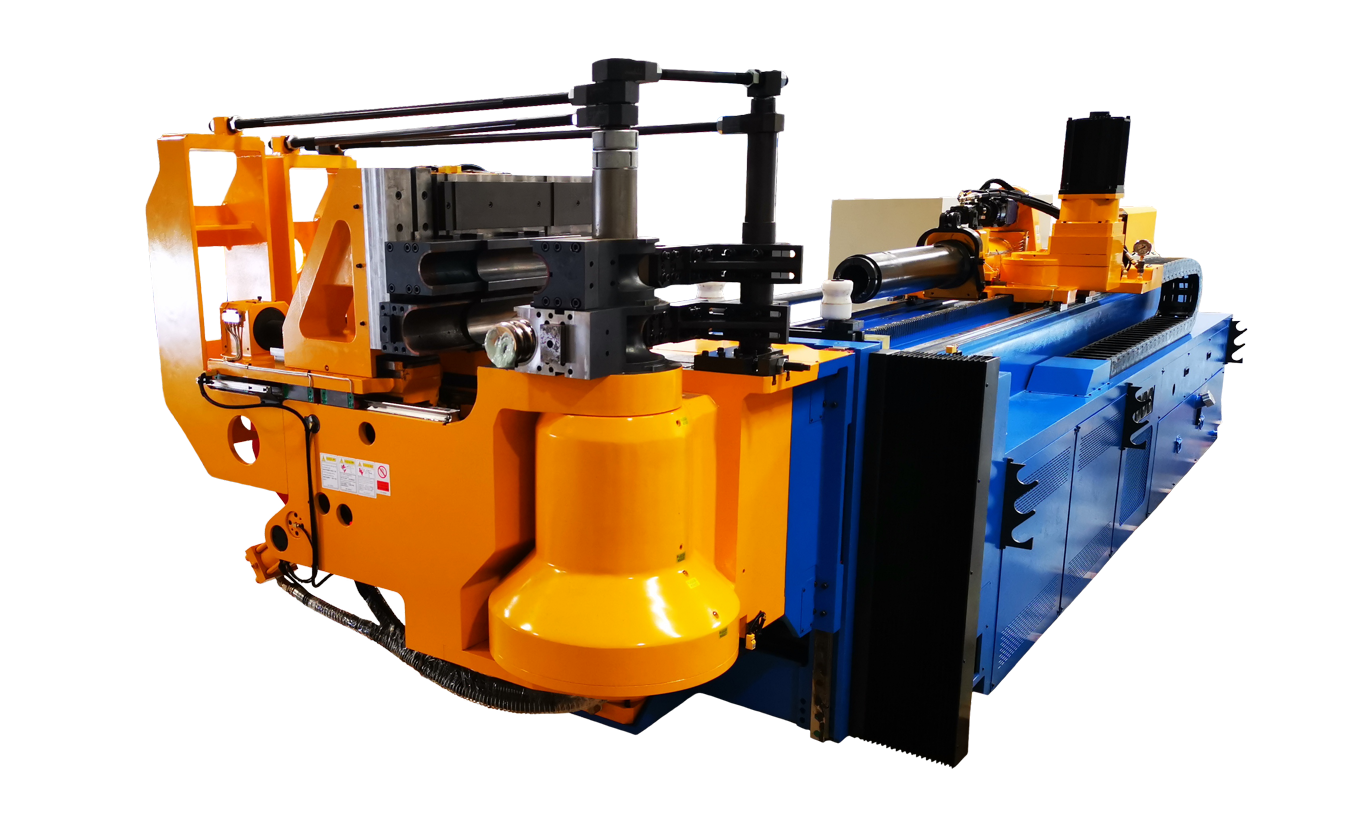

Multi-Stack Hybrid CNC Tube Benders with Rear Boost

The Horn Metric MRE models are a multi-stack hybrid CNC Tube Bender with servo controlled X & Z axis movement with the additional capability of rear boost to aid in producing tight radius bends. The carriage boost system provides the ability to mandrel bend tight radius tubes or push roll large radius sweeps on the top stack.

This value priced all-electric machine features automatic and precise positioning of the tooling for fast setups and reduced scrap. Most brands and types of existing tooling can be used on this machine.

General Info: MRE Hybrid CNC Tube Bender

- Electric/Hydraulic Hybrid CNC Tube Bender

- Electric drive bending with hydraulic tooling actuation

- BendPro CNC controls with full simulation capability

- Multi-stack capability with Servo driven up, down, & side bend head movement

- Value priced – a lot of machine for the money

- Bend-arm (C-axis) by servo motor via planetary transmission

- Carriage (Y-Axis) by servo motor with boosting power

- Clamp, Pressure die, & Pressure die assist are hydraulic driven

- Mandrel is hydraulic driven with early withdrawal

- Collet (B-Axis) rotation by servo motor

- Automatic mandrel lubrication

- Automatic tube support

- Environmentally friendly: Small power consumption, low noise & heat

Special Features:

- Programmable Multi-Stack height and Radius

- Roll bending available for large radius

- Carriage Boost for tight radius

Horn Metric MRE – Available Model Specs

Horn Metric 80MRE-RBE

| Specifications | UNIT | IN | METRIC |

|---|---|---|---|

| Bending Capacity / Round Tube / Mild Steel | IN/MM | 3.15 X 0.098 | 80 X 2.5 |

| Bending Capacity / Round Tube / Non-Ferrous | IN/MM | 3.15 X 0.177 | 80 X 4.5 |

| Bending Capacity / Round Tube / Stainless | IN/MM | 2.75 X 0.065 | 70 X 1.6 |

| Bending Capacity / Square Tube / Mild Steel | IN/MM | 2.00 X 0.079 | 50 X 2.0 |

| Bending Capacity / Solid Bar / Mild Steel | IN/MM | 1.378 | 35 |

Horn Metric 100MRE-RBE

| Specifications | UNIT | IN | METRIC |

|---|---|---|---|

| Bending Capacity / Round Tube / Mild Steel | IN/MM | 4.00 X 0.140 | 100 X 3.6 |

| Bending Capacity / Round Tube / Non-Ferrous | IN/MM | 4.00 X 0.255 | 100 X 6.5 |

| Bending Capacity / Round Tube / Stainless | IN/MM | 4.00 X 0.065 | 100 X 1.6 |

| Bending Capacity / Square Tube / Mild Steel | IN/MM | 2.75 X 0.138 | 70 X 3.5 |

| Bending Capacity / Solid Bar / Mild Steel | IN/MM | 1.75 | 45 |

BendPro G2v3 Features & Benefits:

- Most popular CNC bender Control In North America

- Easy to operate and program

- Extremely compact

- 3D simulation

- Teach Mode with anti-interference moves

- Online troubleshooting