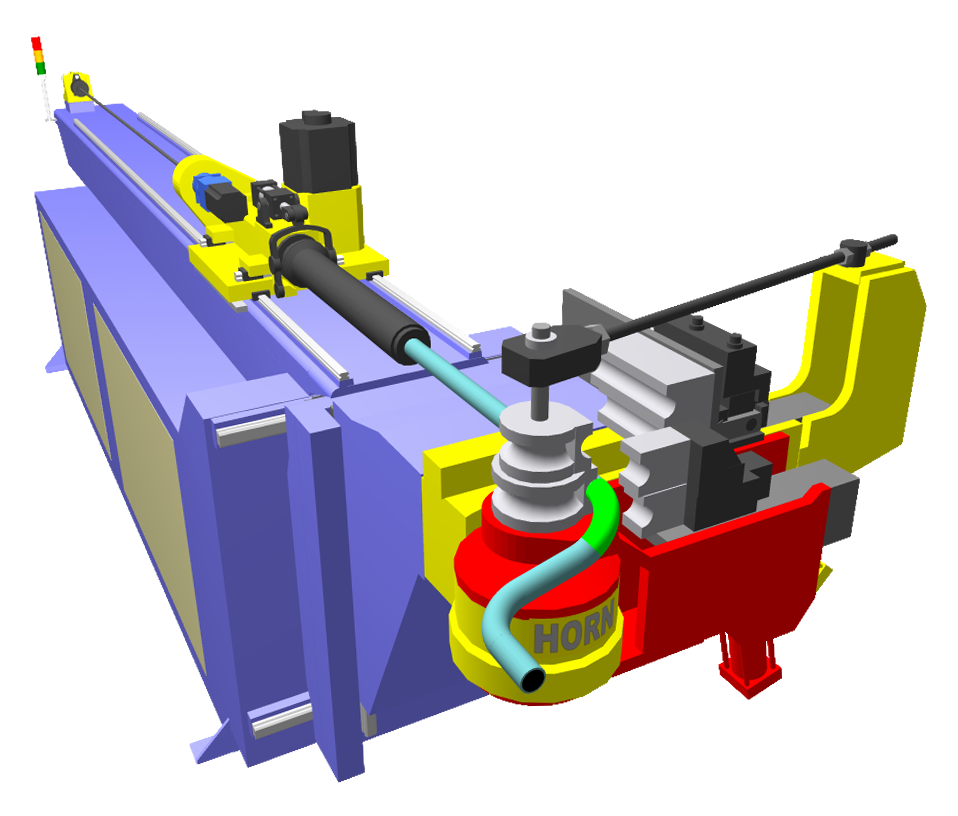

BENDPRO G2 V3 SIMULATION

With BendPro G2 v3 SIM, parts can be simulated on both the bender control itself and also in an office environment. HMT provides all CNC bender controls with simulation capability and includes a 3D model file of the bender. This allows an operator to determine if there is an interference problem before a part is actually bent. Cycle times can then be easily estimated.

CNC TUBE BENDING SIMULATION SOFTWARE

BendPro G2 software features a powerful option called SIM that simulates the bending process and detects potential collisions between the tube, bending machine, and bend tooling. SIM can also be used to determine optimal bending sequences in order to reduce cycle times. In addition, cycle times can be calculated for the purpose of accurately bidding jobs. Detailed 3D tube bender models are animated using the same motion control software that controls the bending machine, resulting in highly accurate simulations.

BendPro SIM IN AN OFFICE ENVIRONMENT

BendPro SIM is the ultimate offline programming tool. Companies that benefit the most from BendPro SIM typically have a need to create multiple part shapes, or are concerned with scrapped tubing costs, or simply want to optimize bending sequences in order to increase production. Furthermore, having BendPro SIM in an office environment allows new operators to be trained quickly and easily. BendPro SIM runs on office PCs and can also be enabled on the BendPro G2 tube bender control.