BENDPRO G2 V3 ROLL FORMING INTERFACE

Not all CNC tube benders have the ability to roll form. As a minimum, the CNC tube bender must be a hybrid or all-electric CNC tube bender with a direct drive swingarm. This is the only way to achieve the accuracy and consistency to make the same part on a repeatable basis.

HMT has provided a phenomenally high number of solutions involving roll forming throughout North America over the course of many years. HMT has the bending & tooling knowledge, and the software experience to ensure that a successful project becomes the end-result.

ROLL FORMING INTERFACE

Horn Machine Tools is one of the tube bending industry’s leading suppliers of CNC tube benders that have roll forming capability. This process is similar to the traditional three roll forming die machines, but uses the force of the CNC bender carriage to push the tube through the rollers.

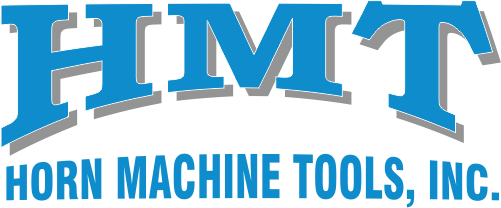

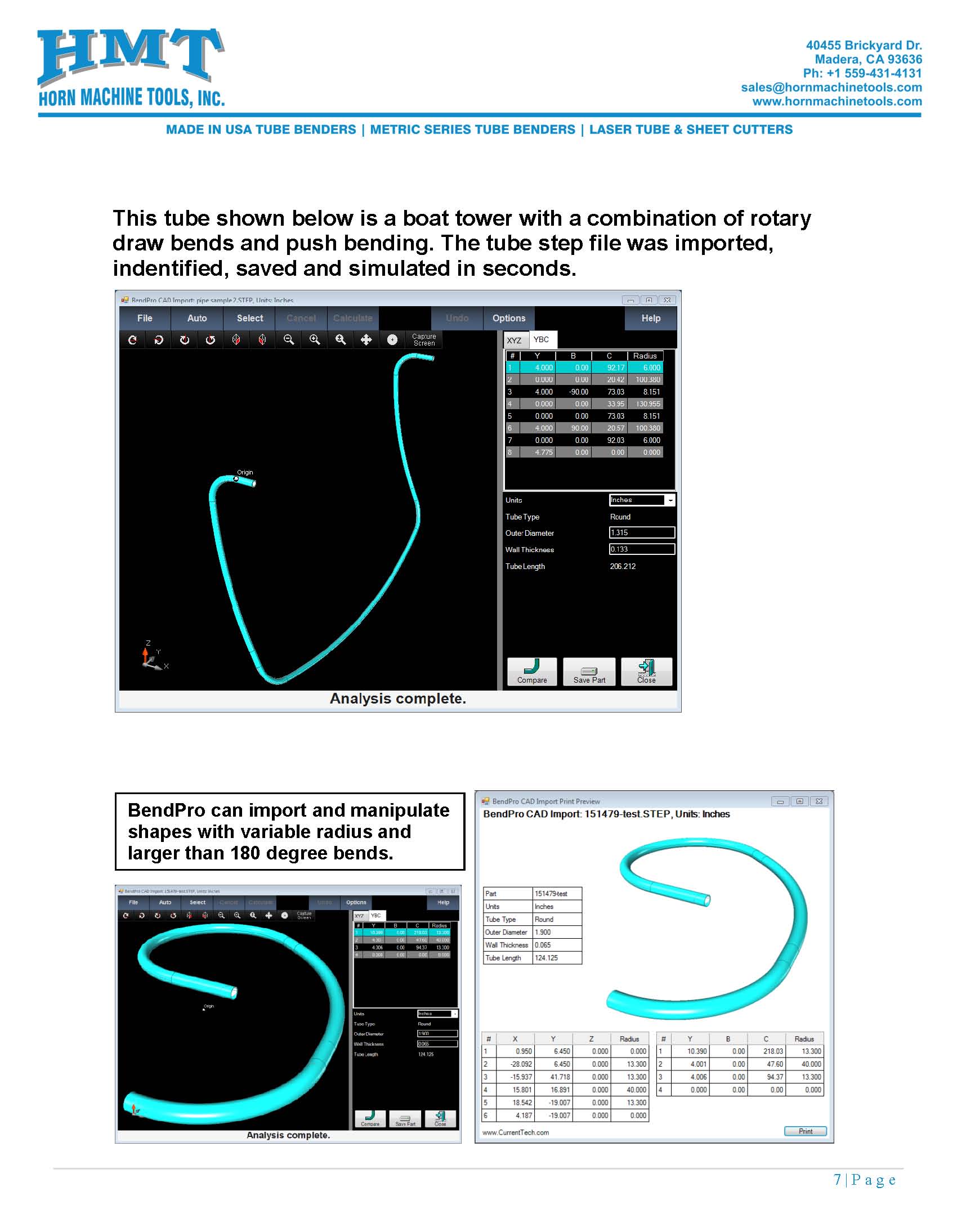

HMT was the first company to prove and develop push bending using the BendPro G2 control system. We assisted in the design and development of the screen and methods used to control the arc length and radius generation.

Advantages over traditional roll forming

- The arc length of the bend is precisely controlled

- 3D shapes such as spirals and helixes

- Tight radius draw bends and large radius roll forms can be made in the same machine setup