BENDPRO G2 V3 DEVELOPMENT WIZARD

BendPro G2 was designed with ease of use in mind and is based on the Windows operating system. From the Master Menu, the operator can operate the bender as well as quickly access all other control screens. A graphical representation of the bender and its functions are displayed on a rugged, high-resolution touchscreen. The Master Menu is designed to effectively communicate production status and machine status, including any warning messages or alarms that might require attention.

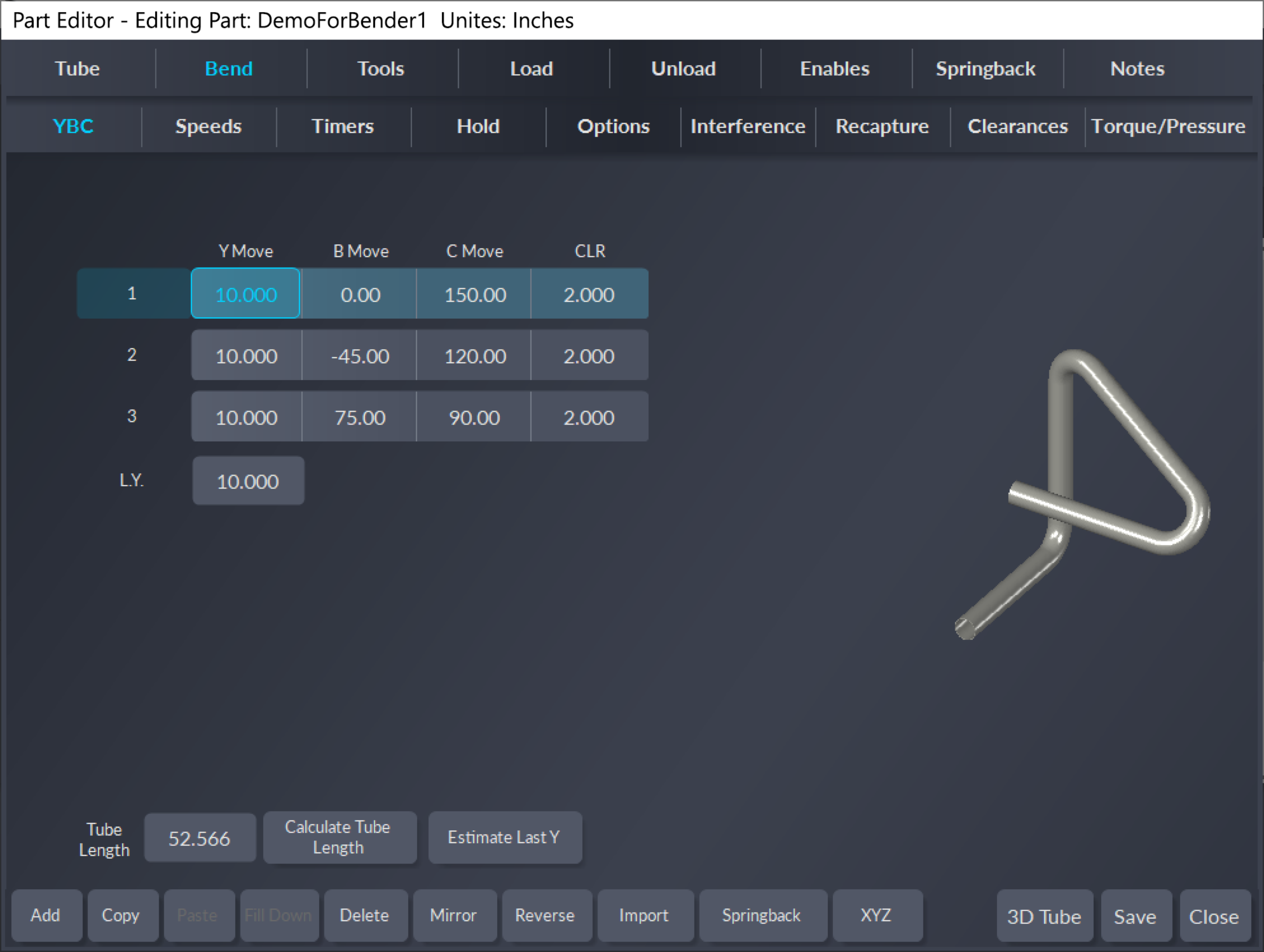

INTUITIVE PARTS EDITOR

New customers are surprised by how quick and easy it is to program parts in BendPro G2, especially when compared to other control systems. The software’s Parts Editor is designed to make data entry and editing intuitive and easy.

Bend data can be entered in the form of XYZ Cartesian coordinates, or YBC (LRA) data. The software can convert back and forth between XYZ and YBC bend data. With the touch of a button the bend sequence can be reversed or mirrored. Advanced line editing functions include Add, Delete, Insert, Copy, Paste, and Fill Down.

Any programmed part can be displayed in 3D for the purpose of verifying the shape and bending orientation. Command buttons are included for rotating, spinning, panning, zooming, etc.

The tube can also be animated to show the bending orientation. A screen capture button allows copy and paste functions into Windows programs including Outlook.

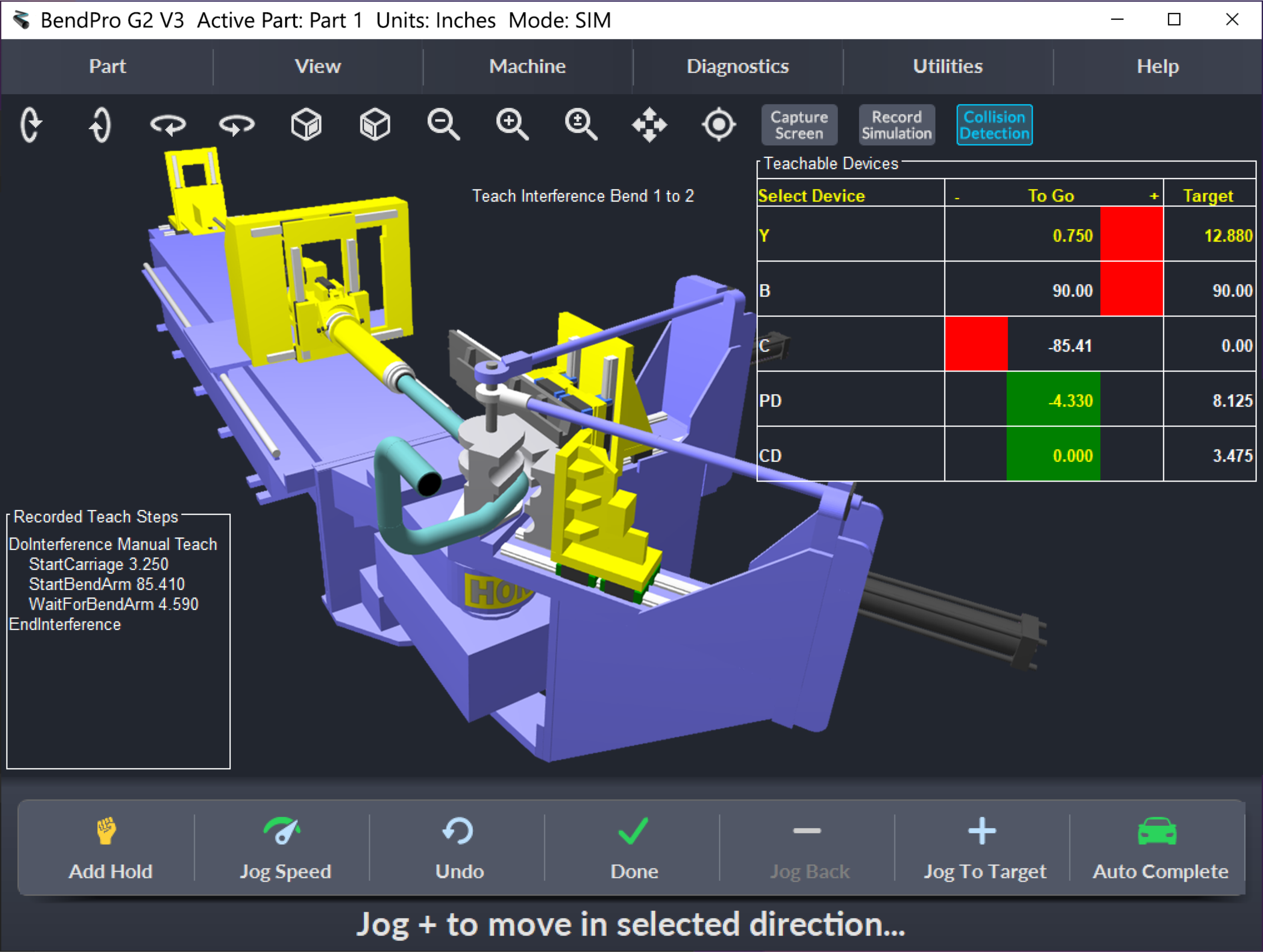

PROGRAM AVOIDANCE MOVES

Programming avoidance (interference) moves is often a complicated and time-consuming process with other bender controls. BendPro G2 has several options to make programming avoidance moves quick and easy.

Teach Mode is the most commonly used option because it is extremely intuitive and powerful. With Teach Mode, the operator uses the console joystick to jog each axis to the target position (next bend location). Each move or combination of moves is recorded, allowing the control to play back the moves in exactly the sequence desired. Teach Mode is used for programming avoidance moves and for optimizing bending sequences to increase production. Teach Mode works in CNC mode (live on the bender) or in Sim Mode (3D Simulation Mode).