BENDPRO G2 V3 CMM INTERFACE

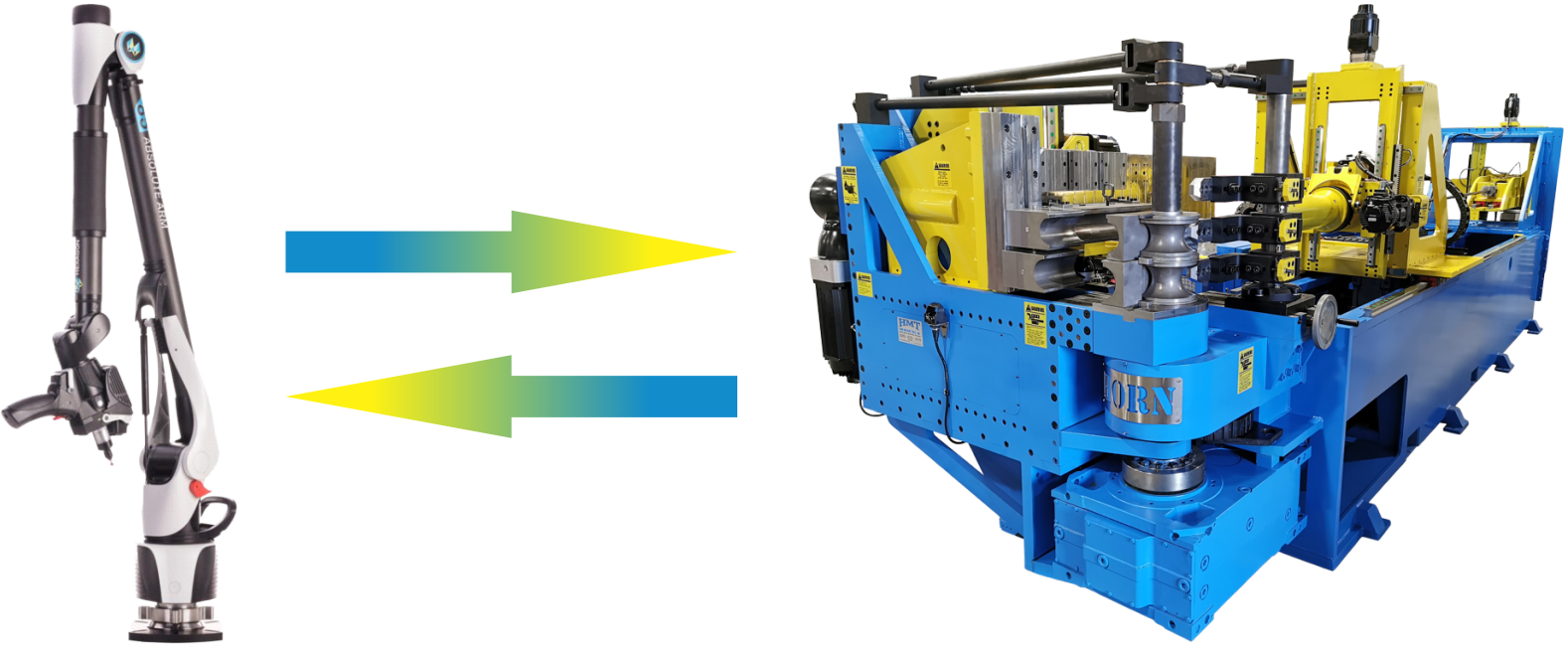

Typically, a master part program is stored in the CMM Library. The CMM is then used to measure a part bent by the CNC tube bender and if the part is not in tolerance, corrections are automatically sent to the CNC tube bender. This process eliminates manual corrections and guesswork that can occur during part development or when a new heat of material is used in the production process.

CMM INTERFACE – CORRECTIONS

BendPro G2’s measuring machine interface is used to create a bi-directional part data corrections loop between a CNC tube bender running BendPro and a coordinate measuring machine (CMM). The CMM must have software capable of utilizing the Supravision Network Protocol (SNP). Software programs include V-Tube Laser, BendingStudio, TeZetCad, etc.

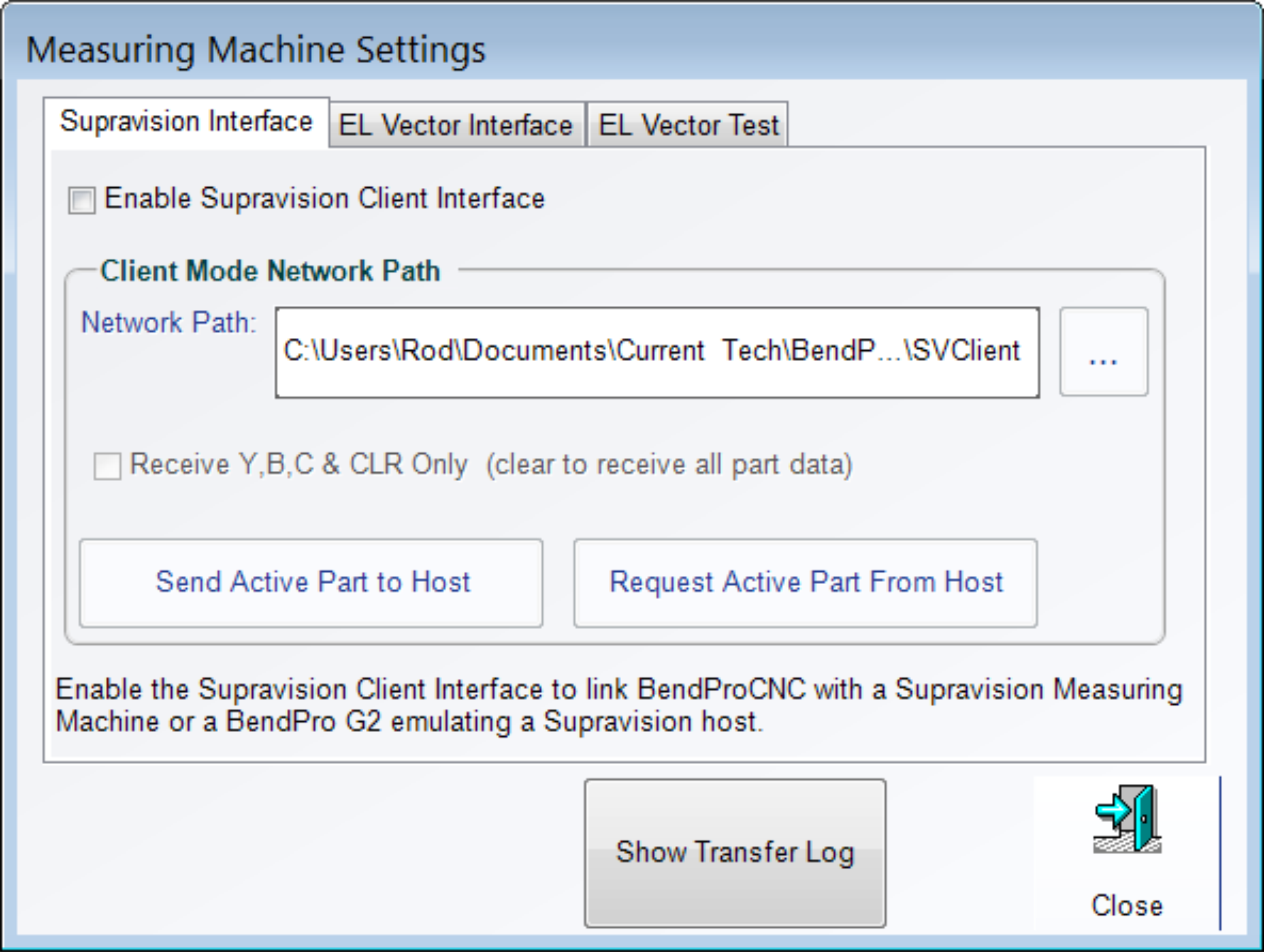

CMM INTERFACE – SUPRAVISION NETWORK PROTOCOL

Supravision Network Protocol (SVNET) uses a local network connection between the bender and the CMM PC. The protocol requires both computers to have access to a shared folder. Files are written to and read from this folder to send parts back and forth. This folder must be setup with read/write permissions and can be located on the CMM PC or on a network.